Product assebly examples and results(reference、Introduction and success)

As many as over 1,000 companies have adopted our machines. Staff members of some of them told us that they won president awards. Many companies feel reliance on us as a manufacturer that not only provides machinery, but also makes efforts to improve quality in cooperation with the customers.

Examples of impressive labor saving(Examples of introduction)

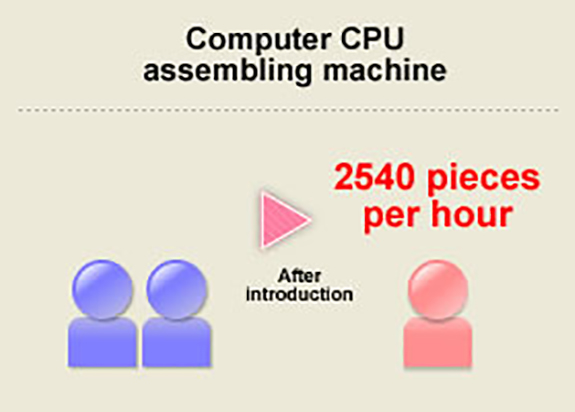

Company A(Electronic parts manufacturer)

Introduced equipment = Computer CPU assembling machines

Before introduction, parts were manually assembled and two persons were required to assemble 720 pieces (CPUs) per hour. After introduction, one person could assemble 1270 pieces (CPUs) per hour. This was a drastic improvement. Then they introduced one more machine so now one person could assemble 2540 pieces (CPUs) per hour. The production capacity became No. 1 at that time and the number of workers was reduced to 1/4. (A total of nine machines have been adopted to date.)

* The staff choosing Ikeda's machine won a president award.

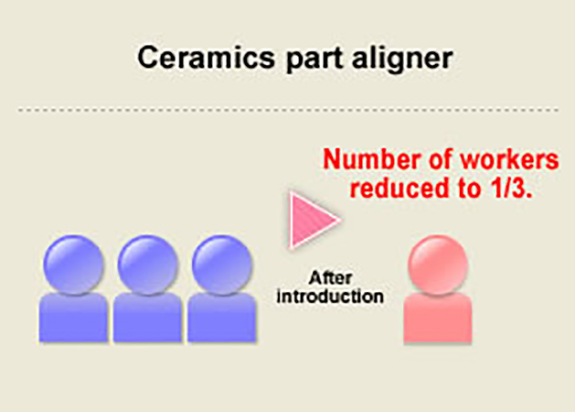

Company B(Semiconductor/electronic parts manufacturer)

Introduced equipment = Ceramics part aligner

Ceramics parts were manually arranged on a jig before fed into an oven. They had to align products on jigs, which then had to be stacked over each other. This work required three persons. After introduction, Ikeda's part aligner has performed most of these jobs and drastically reduced the number of workers to 1/3.

* The staff choosing Ikeda's machine won a president award.

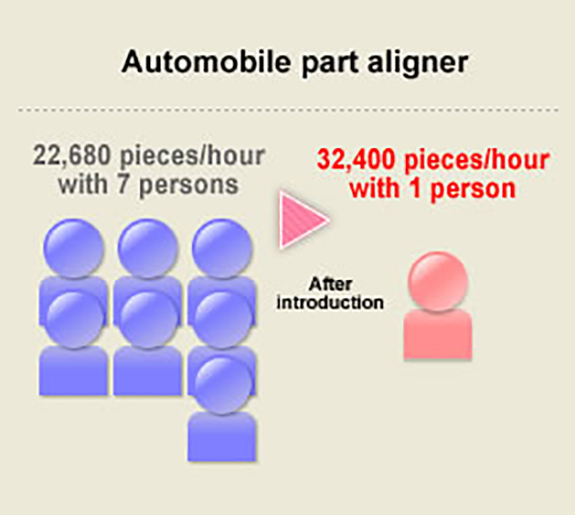

Company C(Automobile parts manufacturer),Korea

Introduced equipment = Automobile part aligner

Since the parts were fragile, they employed seven part-time workers for manual part alignment. They aligned 22,680 pieces per hour. When reviewing their facility, they recognized the characteristics of the product and considered introduction of aligning machines that kept parts from damages. After introducing Ikeda's aligner, one worker could align 32,400 pieces per hour. Six workers were saved and the revenue increased dramatically.

* The staff choosing Ikeda's machine won a special award.