Introduction of assembly products

Purposes of using pallets (alignment jigs)

The greatest feature of the pallets is that parts can be aligned in any desired posture and fed to the next process. Therefore, you can use the pallets having the aligned parts on them, as they are, in image inspection machines, automatic assembly machines, and for part classification for cleaning. The pallets can be used in more various applications by transferring the work to customer's jigs.

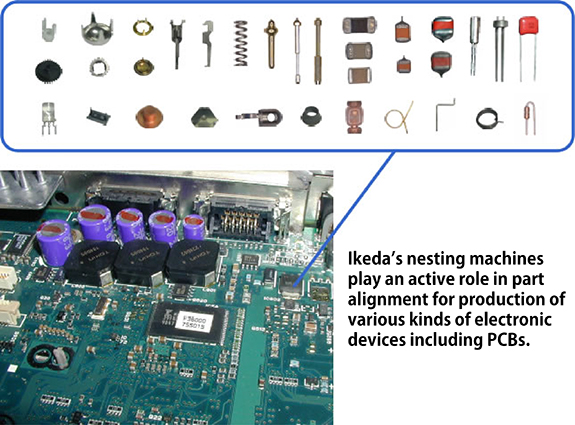

As another feature, Ikeda's nesting machines can also assemble customer's parts. Many and various parts can be assembled at a time by aligning them on pallets and supplying them on a flat surface. By increasing work efficiency and shortening time, as a result, Ikeda's nesting machines can drastically reduce the production costs, thus the product unit prices.

We can design a nesting machine so that parts can be fed to the customer's process after assembled partially, not completely.

Changes of used parts are supported flexibly by using pallets. Ikeda's nesting machines can satisfy you even in cases where you need to frequently change parts or types of parts for higher competitiveness.

Parts that can be aligned

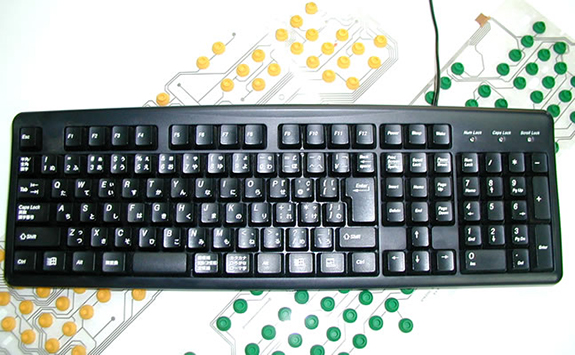

Example of alignment of rubber springs.

Various layouts can be addressed just by replacing pallets (jigs).

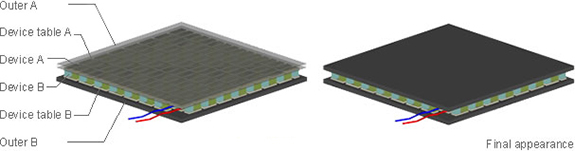

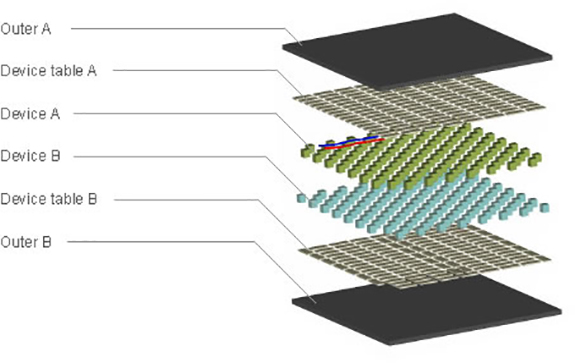

Assembly of flat parts

Flat parts can be aligned on a flat surface with the same posture and assembled by suction and transfer.

Assembly example: Thermo modules

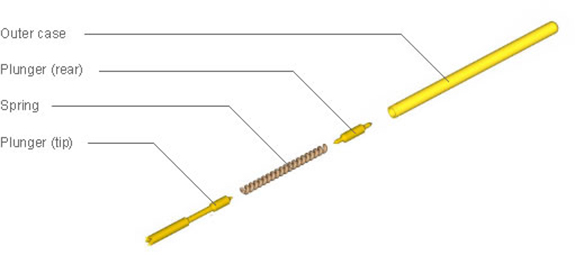

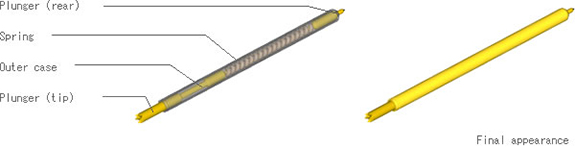

Assembly of long parts

To assemble long parts, the nesting machine first aligns them on a flat surface, then sweep them with an upright pallet. In addition, parts can also be press-fit.

Assembly example: Contact probe for inspection