Company Information

Company Outline

| Company Name | Ikeda Jidokiki Co., Ltd. | |

|---|---|---|

| Head Office and Factory | 4-18-17 Higashi-Komatsugawa, Edogawaku, Tokyo 132-0033, | |

| TEL | +81-3-5674-3161 | |

| FAX | +81-3-3869-3641 | |

| Established | June 1, 1979 | |

| Capital | 10 million yen | |

| President | Omori Minoru | |

| Main equipment | Machining center Vertical milling machine Ordinary lathe Engraving machine Tool polishing machine Material cutting machine Non-contact 3D imaging measuring machine Digital measuring microscope CAD computer for design CADCAM for 3D processing Linear height gauge Blasting equipment High-pressure washing machine | 12 2 1 1 3 3 1 1 6 1 1 1 1 |

Corporate History

| 1970 | Manufactured first progressive automatic nesting machine (type M1). |

|---|---|

| 1976 | Assembly line of ignition nozzles of disposable cigarette lighters was completed. |

| 1979 | Manufactured first automatic nesting machine (type T1). |

| 1982 | Connector line for electronic equipment was completed. |

| 1985 | Line with silver solder for PGA pins was completed. System to align crystal boards before evaporation was completed. |

| 1990 | Automatic assembly transfer machines for PGA packages were developed and many of them were delivered. |

| 1992 | To improve the performances and the safety levels of the automatic nesting machines, new models were brought out and compact machines were developed to satisfy the new demands. |

| 1989~1992 | Automatic line to assemble switches and receptacles was completed. |

| 1994 | Automatic equipment to assemble keyboard rubber springs was developed and many were delivered. |

| 1996 | Introduced touch panel controllers that store 100 programs of data. |

| 1998 | Automatic nesting machines of the low-vibration balancer type (type VB) were developed. |

| 1999~2005 | Automatic nesting machines and transfer machines for various electronic device components, such as chip condensers, were developed based on low-vibration nesting machines and many of them were delivered. |

| 2006~2009 | Developed an automatic transfer and relocation device for ultra-thin electronic components (t=0.025), and delivered a large number of units. |

| 2010 | The TI-20V model has been renewed and changed to the low-vibration balancer type TI-20VB model. It can also be installed on a desktop. |

| 2011 | The control box has been model-changed, adding a part name management function to significantly improve usability. The vacuum workbench has been model-changed for cost reduction. An inverter function has been added to adjust the suction power. |

| 2012 | The delivery of a fully automatic assembly and transfer line for airtight terminals. |

| 2014~2019 | Developed various automatic transfer and press-fitting devices, and delivered a large number of units. |

| 2016 | With some modifications to the TI-20VB model, rigidity has been improved. |

| 2018 | Developed an automatic machine and assembly device for optical components. |

| 2022 | Developed an automatic arrangement device for optical components. |

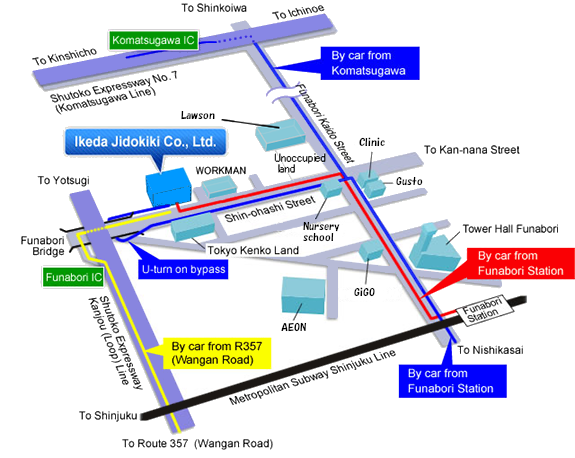

Access

| 4-18-17 Higashi-Komatsugawa, Edogawaku, Tokyo 132-0033, Japan | |

| Tel | 03-5674-3161 |

| FAX | 03-3869-3641 |

| Train | 7 minutes on foot from Funabori Station of Metropolitan Subway Shinjuku Line Take either "Shinko 21" bus bound for Nishikasai Station or "Shinko 21" bus bound for Funabori Station. Get off at Funabori Station. |

| Bus | Metropolitan bus from the South Exit of JR Shinkoiwa Station |

| Bus from the Haneda Airport | Bus stop No.6 (Tourist Terminals #1 and #2) -> Get off at Ichinoe Station and transfer to Metropolitan Subway Shinjuku Line (Ichinoe Station) -> Funabori Station |

| Train from Tokyo Station | JR Sobu Line (rapid service) -> Get off at Bakurocho Station and transfer to Metropolitan Subway Shinjuku Line (Bakuro Yokoyama Station) -> Funabori Station |

Customers

Main customers

- ANZEN MOTOR CAR CO., LTD.

- ICREX CO., LTD.

- Aisin Seiki Co., Ltd.

- Asahi National Lighting Co., Ltd.

- ITEC-Tsuritani CO., LTD.

- ICS

- Oki Electric Industry Co., Ltd.

- Allied Material Corporation

- Iguchi Gomu Kogyosho

- Ukoudenshi CO., LTD.

- Ubukata Industries Co., Ltd.

- SMC CORPRATION

- Omron Corporation

- Olympus Optical Co., Ltd.

- Okayama Murata Manufacturing Co., Ltd.

- Kanazu Murata Manufacturing Co., Ltd.

- Kyocera Corporation

- Gokosha

- Komatsu Electronics Inc.

- Komatsu Murata Manufacturing Co., Ltd.

- Sabae Murata Manufacturing Co., Ltd.

- Sanwa Koki Co., Ltd.

- Sumitomo Metal (SMI) Electronics Devices Inc.

- Sumitomo Metals

- Sumikin Ceramics Co., Ltd.

- Sumiden Fine Conductors

- Sony Corporation

- Tachikawa Kiko

- Tanaka Kikinzoku Kogyo K.K.

- Denken Tanshi Co., Ltd.

- Tokyo Electron Device Limited

- Toshiba Corporation

- Toshiba Components

- Toho Kinzoku Co., Ltd.

- Naoetsu Denshi Kogyo

- Nichicon Tantalum

- Fuji Manufacturing Co., Ltd.

- Matsushita Electric Works, Ltd.

- Minebea Co., Ltd.

- Murata Manufacturing Company, Ltd.

- Rika Denshi Co., Ltd.

- Rohm Mechatech Co., Ltd.

- Nippon Sheet Glass Co., Ltd. Spacia

- Emerson Japan, Ltd.

- Nippon Seiki Co., Ltd.

- Hitachi AIC

- Pilot Precision

- Ferrotec Corporation

- Fuji Denka Inc.

- Fukui Murata Manufacturing Co., Ltd.

- Matsue Matsushita Electric Industrial Co., Ltd.

- Mitsubishi Materials Corporation

- YAZAKI CORPORATION

- TDK Corporation

- Hakusan .Mfg.Co.,Ltd.

- NEC Corporation

- Kenwood Device

- Hirai Seimitsu

- Hitachi, Ltd.

- Hitachi Haramachi Electronics Co., Ltd.

- Toyo Denpa

- Tokuriki Honten Co., Ltd.

- Nippondenso Co., Ltd.

- Japan Radio Co., Ltd.

- Fujitsu Limited

- Sitech

- Sanjo Seiki Co., Ltd.

- Nichicon Corporation

- Nikko Co.

- Shanghai Kyocera Electronics Co.,Ltd.

- Toitsu Co., Ltd.

- Shonaka Seisakusho Co.,Ltd.

- NEC Glass Components, Ltd.

- Kyocera Kinseki Corporation

- Fuji Electronics Co.,Ltd.

- Fuji Electronics Industries Co.,Ltd.

Others

Listed in random order